Analysis of copper ore processing

Copper ore is a core raw material for the metallurgical industry and the production of copper products. Common industrial minerals include native copper, chalcopyrite, bornite, chalcocite, azurite, and covellite. Raw ore requires specialized beneficiation and smelting processes to be transformed into high-purity copper metal and various products. The initial processing aims to enrich useful minerals through physical methods to obtain high-grade copper concentrate or copper ore sand, laying the foundation for subsequent smelting and purification.

Detailed Explanation of Beneficiation Process

Beneficiation is the core link in improving copper grade. Its crushing and screening process mainly includes three key stages:

1. Primary Crushing (Coarse Crushing)

Process: Large pieces of raw ore are fed evenly and continuously into a jaw crusher by a vibrating feeder.

Purpose: To perform preliminary crushing, significantly reducing the ore particle size and creating conditions for subsequent medium and fine crushing.

2. Medium and Fine Crushing (Secondary Crushing)

Process: The ore after coarse crushing is transferred to a cone crusher via a belt conveyor.

Objective: To perform secondary crushing to further reduce the particle size of the ore to meet the particle size requirements of subsequent sorting operations.

3. Sorting and Enrichment

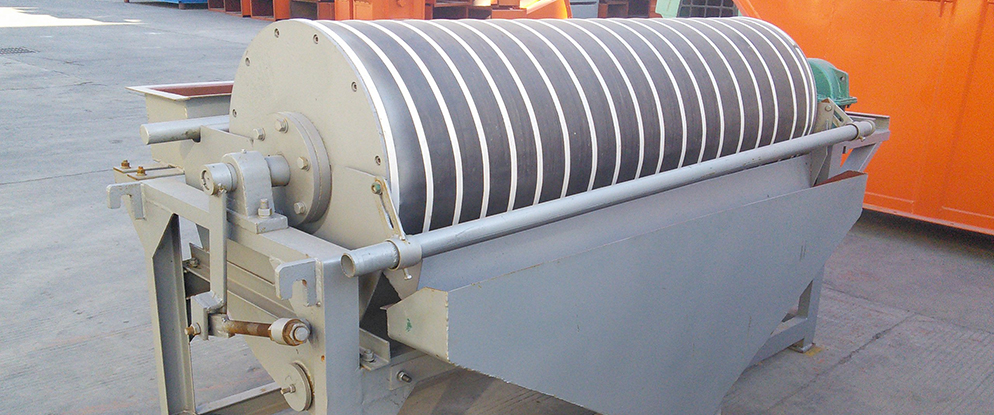

Process: Material crushed to 0.5-5 mm is fed into a hopper, where a vibrating motor ensures uniform distribution, and then it enters a magnetic roller for sorting.

Objective: To effectively separate copper-bearing minerals from gangue or iron-bearing impurities by utilizing the magnetic differences between minerals, ultimately producing copper concentrate.