04 December 2025

Mineral processing is the process of separating valuable minerals from gangue minerals in ore based on the physical and chemical properties of different minerals in the ore. After crushing and grinding, methods such as gravity separation, flotation, magnetic separation, and electrostatic separation are used to separate valuable minerals from gangue minerals, and to separate various associated (symbiotic) valuable minerals as much as possible, removing or reducing harmful impurities to obtain raw materials needed for smelting or other industries. Mineral processing can enrich the valuable components in minerals, reduce fuel and transportation consumption during smelting or other processing, and make low-grade ores economically usable.

Mineral processing utilizes the differences in the physical or physicochemical properties of minerals, using various mineral processing equipment to separate valuable minerals from gangue minerals in the ore, and to relatively enrich the valuable minerals. Industrially, mineral resources can be divided into metallic, non-metallic, and combustible organic mineral resources. Except for a few rich ores, most are of low grade and require processing before utilization; mineral processing is the main processing step.

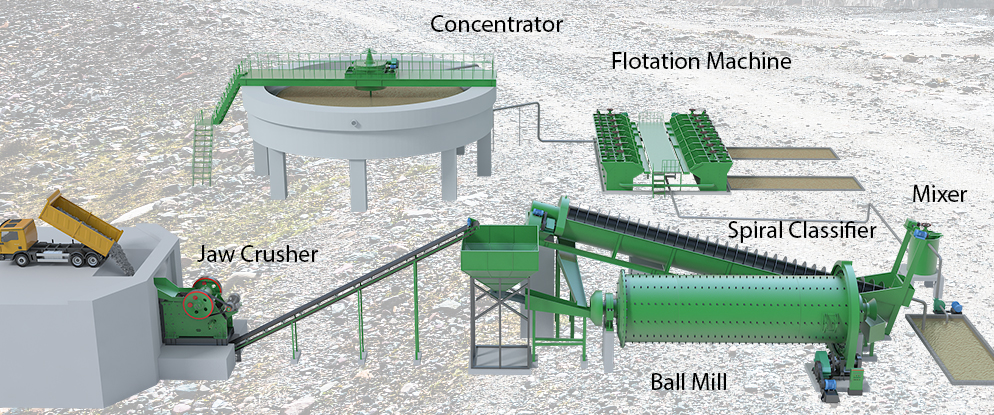

The mineral processing technology is a core technology system in the metallurgical field, mainly composed of three core links: crushing, grinding, and separation. Traditional mineral processing techniques separate valuable minerals from gangue minerals using physical or chemical methods. For example, gold ore beneficiation widely employs a combined process of flotation and carbon-in-water leaching, while rare earth ore beneficiation utilizes a composite process combining flotation and hydrometallurgy.

The beneficiation process requires the coordinated operation of various equipment, primarily including three categories: crushing equipment, grinding equipment, and separating equipment. These devices work together to complete the entire process from ore crushing to the enrichment of valuable minerals. The specific type of equipment selected depends on the ore properties and process requirements.

As a core component of mineral resource development, mineral processing technology directly impacts the effective utilization of mineral resources and environmental protection. Currently, the mineral processing industry is developing towards large-scale, intelligent, and green practices, with technological innovation continuously driving industry progress. In the future, with the in-depth application of digital technologies and increasingly stringent environmental requirements, mineral processing technology will become more efficient, intelligent, and environmentally friendly, providing strong support for the sustainable development of mineral resources.